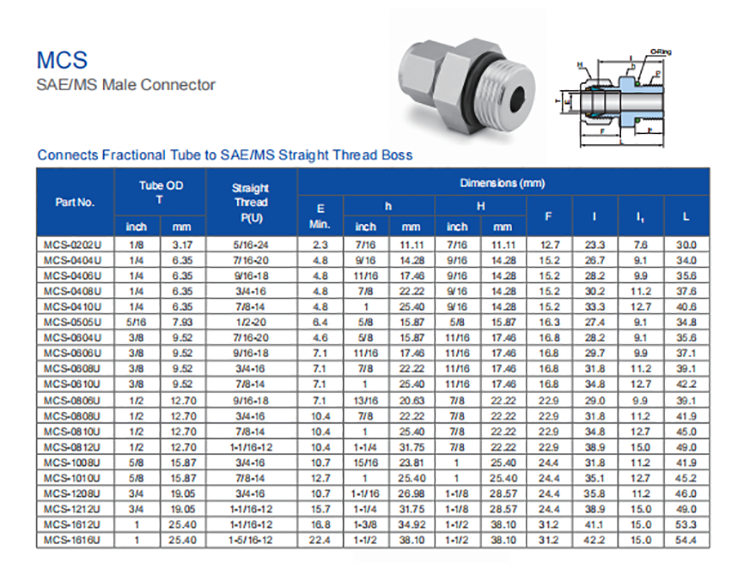

O-seal fitting Male SAE 6mm od X 1/4 BSPP

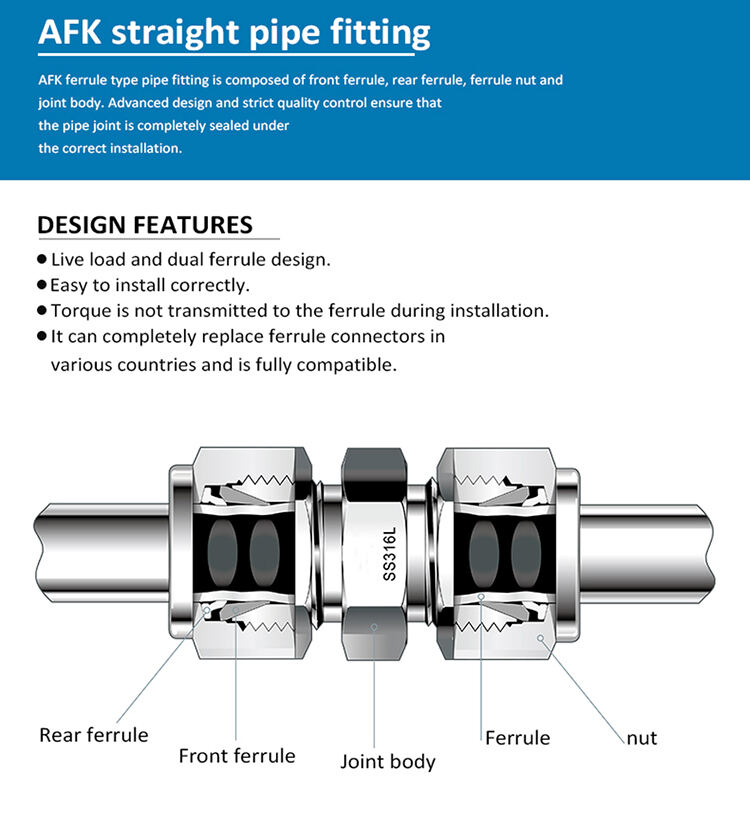

AFK is constantly improving the leak-proof design of its tube fittings to enable them to be used in thousands of applications, including research, analytical and process testing instruments, bioengineering, oil and gas, power, petrochemical, and semiconductor industries, and focuses on the following key issues:

①Leakage ②Vibration (tube grip) ③Thermal shock ④Compliance with industrial standards ⑤Installation ⑥Corrosion

| Product name | Union Tee |

| Standards: | Ferrule to male |

| Sizing: | 1/16"OD TO 2"OD |

| Material: | 316 Stainless steel |

| Working Pressure: | 250bar |

| Tempreture: | -60℃~400℃ DIN 17440 |

| Warranty: | 1 year |

| Support: | OEM, ODM |

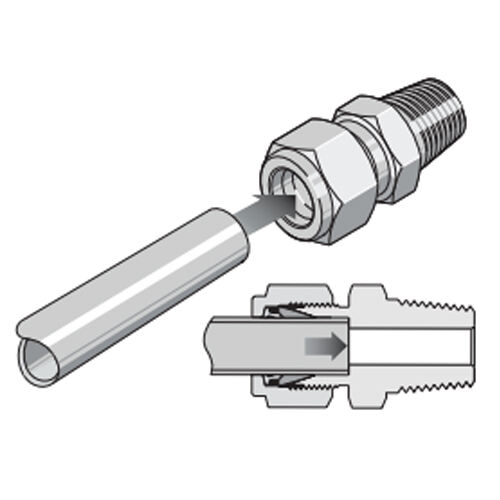

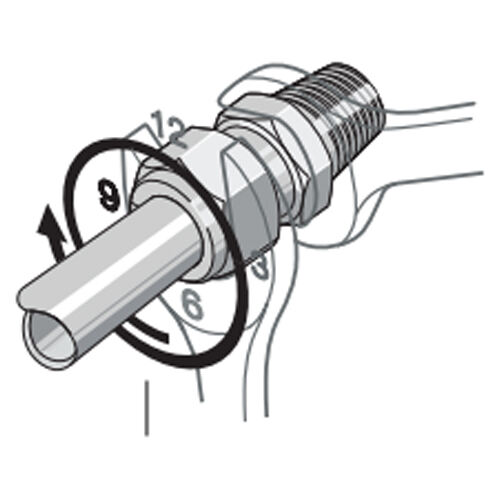

Step 1

Insert the tube fully into the fitting and against the shoulder; finger-tighten the nut. High pressure applications and high safety systems: further tighten the nut so that the tube cannot be turned by hand or moved axially in the fitting

Step 2

Mark the nut at the 6 o'clock position

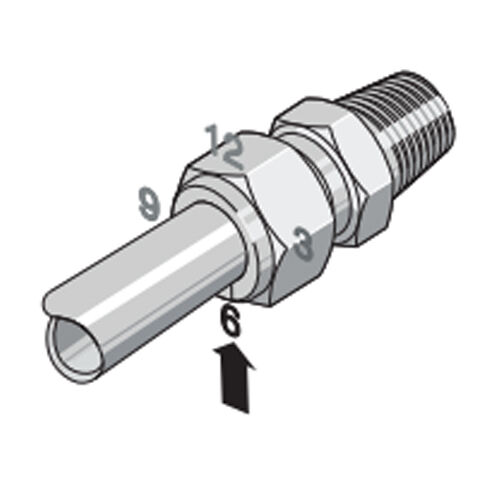

Step 3

With the fitting body securely fastened, tighten the nut one and one-quarter turns to the 9 o'clock position For 1/16, 1/8 and 3/16 in.;2, 3 and 4 mm tube fittings, tighten the nut only three quarters of a turn to the 3 o'clock position

Safety precautions

Do not vent the system by loosening the fitting nuts or by blocking the fittings. Do not install or tighten fittings while pressure is present in the system --- Ensure that the tube is tight against the shoulder of the tube fitting body before tightening the nut, and use the correct gap detection gauge for the first installation to ensure adequate tightening. Always use the correct thread sealant on tapered pipe threads -- Do not mix fitting components tubing, ferrules, nuts and fitting bodies made of different materials or by different manufacturers -- Do not rotate the fitting body. Instead, secure the fitting body and rotate the nut. Avoid unnecessary disassembly of unused fittings. Only use long reducers in AFK female end connections.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

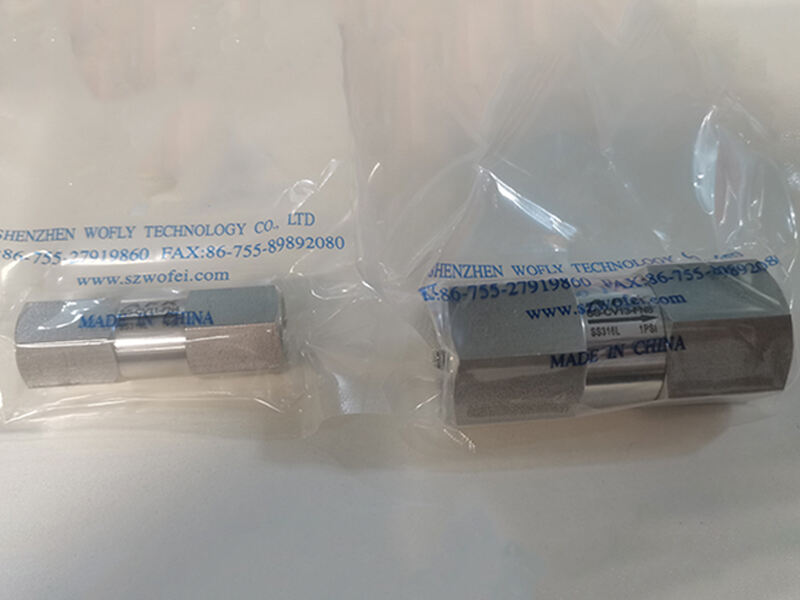

Introducing, the AFKLOK’s Type P O-Seal Ring fitting. This high-quality fitting is perfect for those looking for a reliable Male SAE 6mm od X 1/4 BSPP fittings that can withstand even the toughest conditions. Made from durable stainless steel, this fitting was built to last and is sure to be a staple in any tool kits.

One for the key features of it is its versatility. This fitting can be used in a variety of applications and is perfect for those that requires a fitting that can use a selection of different systems with a BSPP x Tube Compression Fitting.

It is also extremely very easy to install in addition to its versatility. This fitting could be quickly and easily installed with just a few simple tools whether you are an experienced professional or even a DIY enthusiast. Plus, the o-seal ring insures a secure and leak-free connection, giving you peace of mind that your system is being employed as it should.

One of the best features of it is that it is incredibly durable. Produced from top-quality stainless steel, this fitting can withstand even the toughest conditions. This fitting is sure to hold up and keep your system operating smoothly whether you are working in extreme temperatures or working with harsh chemical compounds.

The AFKLOKs Type P O-Seal Ring fitting is a must-have for anyone in need of a reliable and versatile fitting. With its BSPP x Tube Compression Fitting and o-seal ring design, it is easy to install and ensures a secure and leak-free connection. And, with its durable stainless steel construction, you can be sure that it will hold up even in the most challenging of conditions. So, why wait? Add the AFKLOK’s Type P O-Seal Ring fitting to your tool kit today and experience the difference for yourself.

Our friendly team would love to hear from you!