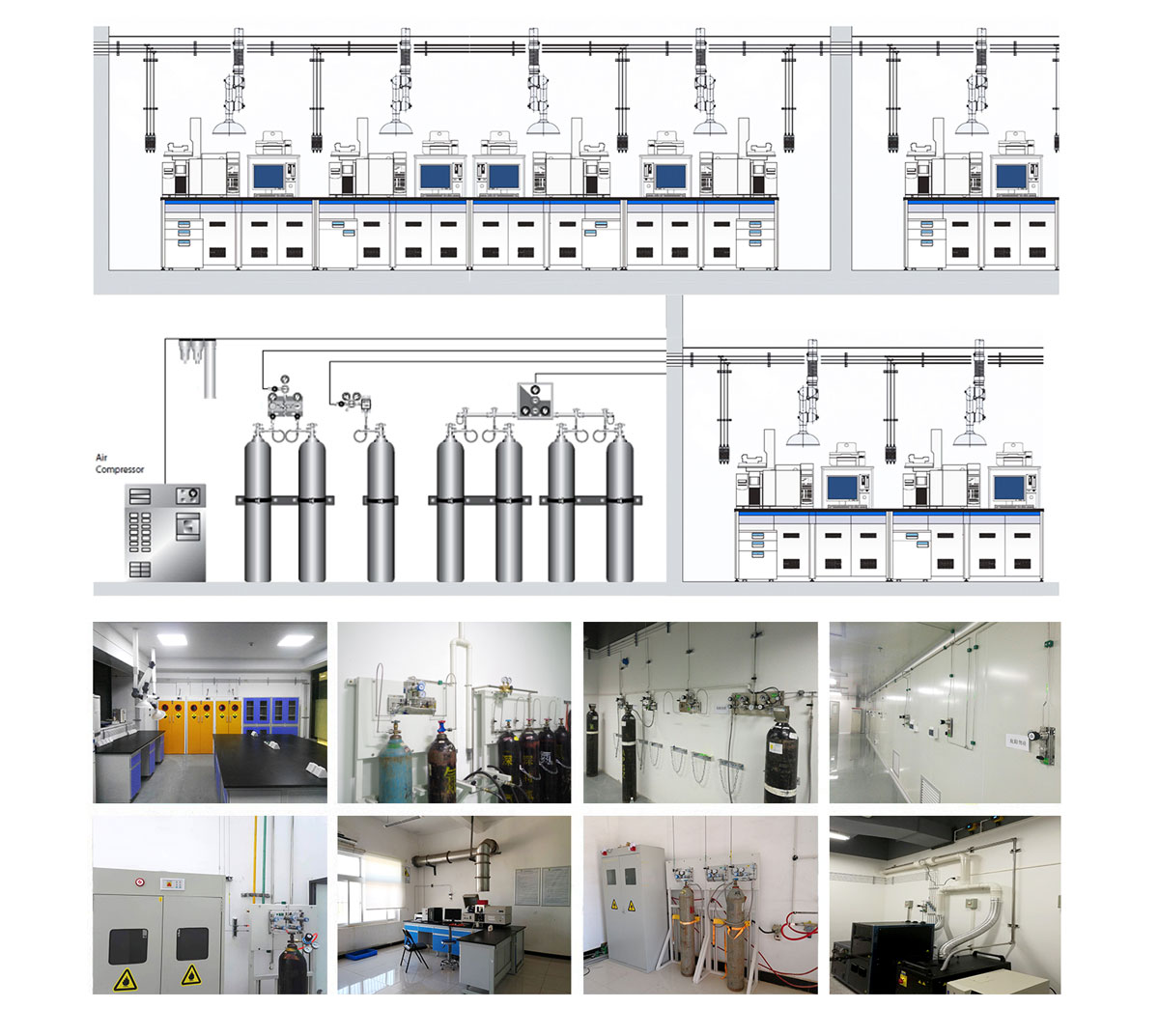

Clean Nitrogen Pipeline Air Supply Introduction

All high purity, highpurity in the clean nitrogen pipe is required to be delivered to the instrument(POU) through the pipeline. In order to achieve the quality requirements of theinstrument, in the case of gas outlet indicators, it is necessary to pay moreattention to the pipe system, material selection and construction quality. Inaddition to the accuracy of the gas or purification equipment, it is largelyaffected by many factors of the pipeline system. Therefore, the selection ofpipes should abide by the relevant industry principles, and indicate thepipeline material.

The material of the clean nitrogen pipeline is selected according to theneeds of the use, and the 316L BA is commonly used in contact with the chip butdoes not participate in the process reactive. The surface roughness in the tubeis a standard for measuring the quality of pipe. The lower the roughness, theparticle carrying possibilities are greatly reduced.

Clean nitrogen pipelines can absorb about 200 g of gas per ton during thestainless steel smelting material. The stainless steel is processed, not onlythe surface is adhesive, but also a certain amount of gas is also affected inits metal lattice. When there is air flow in the pipeline, this part of the gasresides in the metal will re-enter the airflow, and pollute the pure gas. Whenthe intractive flow of the tube is not continuous flow.

When the pipe is adsorbed under pressure, the gas is adsorbed, the gas isstopped, and the gas adsorbed by the pipe has formed a step-down analysis, andthe parsed gas is also used as impurities into the pure gas in the pipe. At thesame time, adsorption, analyze, so that the surface of the pipe also produces acertain powder, which is also a purified gas in the tube. This feature of cleangas pipeline is critical, in order to ensure the purity of the gas delivered,not only require a very high smoothness of the inner surface, but also high wearresistant characteristics.

When the gas is strong in corrosion, it is necessary to use thecorrosion-resistant stainless steel pipe. Otherwise, the pipe of clean gaspipeline will generate corrosion spots due to corrosion, and there will be largemetal stripping or even perforation, and thereby pollution Pure gas with a puregas.

EN

EN

AR

AR

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ