Product Description

1. Good corrosion resistance

2. High measurement accuracy

3. Good stability

4. Clear reading

5. Safe and reliable

Model No:YXC-63

Dial:63mm

Pressure Gauge Range:0-100psi

Bottom Connection:1-1/2"(50.5mm)

Connection: Axial connection

Body Material:SS316

Specification

| item |

value |

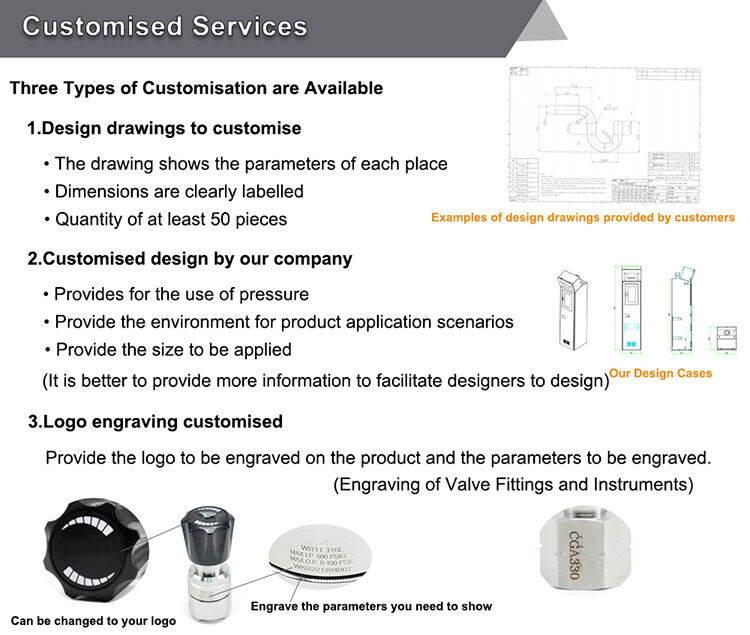

| Customized support |

OEM, ODM |

| Brand Name |

AFKLOK |

| Model Number |

YXC-63 |

| Type |

Low-Pressure Gauges |

| Material |

SS316 |

| Size |

1-1/2in(50.5mm |

| Weight |

0.5 |

| Product Name |

Diaphragm pressure gauge |

| Material |

SS316 |

| Connection |

Axial connection |

| Application |

Measuring gas pressure |

| Pressure range |

0-100psi(0-7bar |

| Dial Size |

63mm |

| Size |

1-1/2in(50.5mm |

FAQ

- 1. What are the accuracy ratings of diaphragm pressure gauge 0 - 100psi

- Common accuracy levels are 1.6, 2.5, etc., but the specific accuracy level varies according to different manufacturers and different product series.

- 2. What dial sizes are available?

- Generally, there are various conventional sizes such as 40mm (1.6 inches), 60mm (2.5 inches), 100mm (4 inches) and so on.

- 3. What are the connection methods?

- There are mainly threaded connections (such as common NPT threads, etc.), flange connections (such as DN25 and other different specifications of the size of the flange) and so on.

- 4. Material of diaphragm?

- 316 stainless steel (suitable for some of the less corrosive media, etc.

- 5. What should I pay attention to when installing?

- The installation position should be easy to observe and operate;

- 1. In case of threaded connection need to ensure good sealing;

- 2. flange connection should ensure that the gasket between flanges is installed correctly and pressed tightly;

- 3. install vertically (except for special cases, but need to correct the error according to the regulations)

- 4. avoid strong vibration;

- 5. avoid installation in strong vibration, strong electromagnetic field interference and other environments

- 6. Does the temperature of the measuring medium have any effect on the diaphragm pressure gauge?

- If the medium temperature is too high or too low, it may affect:

- 1. the performance and volume of sealing liquid (if there is sealing liquid inside), which may affect the pressure conduction and gauge head indication;

- 2. the elasticity and physical properties of the diaphragm itself;

- 3. the overall accuracy of the gauge;

- 7. What will happen if I use it under vibrating working conditions?

- It may lead to jittering of the pointer, difficulty in reading, etc;

- Long-term strong vibration may loosen, deform or damage internal components such as spring tubes, transmission mechanisms, etc; It can be improved by choosing diaphragm pressure gauge with vibration-resistant function or installing vibration-damping device

- 8. How often do I need to calibrate?

- It is usually recommended to calibrate once in 6 - 12 months, if the use of harsh environments (such as severe temperature changes, strong corrosion, strong vibration, etc.) or high requirements for accuracy may need to shorten the calibration period; if used for critical process monitoring or safety monitoring, the calibration period should also be shorter.

- 9. What does routine maintenance mainly include?

- 1. Regular exterior inspection to check for breakage, leakage, abnormal pointers, etc;

- 2. clean the surface to prevent the accumulation of dust, oil, etc. to affect the readings;

- 3. check the connection parts for looseness;

- 4. if it is not used for a long time, it should be stored properly to prevent aging of the diaphragm, etc

Wofly

The Diaphragm Pressure Gauge is the perfect tool to accurately measure gas pressure. Made with high-quality stainless steel 316 this gauge is durable and built to withstand the harsh conditions of industrial settings

With a pressure range of 0-100psi this is ideal for a wide range of applications from heating and ventilation systems to scientific experiments and much more. The Wofly axial connection also makes it incredibly easy to install and use allowing you to quickly and efficiently measure pressure levels

Compact and easy to read allowing you to quickly and accurately monitor gas pressure levels. The clear markings on the dial make it simple to read the pressure level even from a distance

The diaphragm design ensures that it is accurate and reliable allowing you to get consistent readings time and time again. Ideal for use in busy industrial settings where precision and accuracy are of the utmost importance

Whether you are a professional technician scientist or simply need to monitor gas pressure levels for your home heating system this is the perfect tool for the job. With its sturdy construction clear markings and reliable diaphragm design it is a dependable and accurate tool that you can trust to get the job done

Get this now