Product Features

Suitable for continuous gas supply, one end is exhausted and automatically switched to the other end

With air source priority selection handle, you can set the priority air supply

The WR11 pressure reducing regulator is used as the prototype valve, which can be used for corrosive and toxic gases

The WV4H diaphragm valve is used as the prototype valve with two three-way valves and fewer connections

There is a 20μm filter element in the inlet

Oxygen environment application options are available

The output pressure is in a certain range, which has been set before delivery

| item | value |

| Application | General |

| Port Size | 1/4 |

| Warranty | 1 Year |

| Place of Origin | China |

| Hunan | |

| Model Number | DCOS11 |

| Power | Manual |

| Temperature of Media | Normal Temperature |

| Brand Name | AFKLOK |

| Structure | Regulating |

| Cv of Diaphragm valve | 0.17 |

| Customized support | OEM, ODM, OBM |

| Material | 316L SS |

| Max. inlet pressure | 3500 psig |

| Outlet Pressure | 85~115,135~165,185~215, 235~265 psig |

| Working temperature | -40~+165℉(-40~+74℃ |

| Cv of Pressure regulator | 0.09 |

| Applicable gas | O2, N2, CO2, C2H2, C3H8 |

| Application areas | Lab, Semiconductor material, lithium battery, solar photovoltaic |

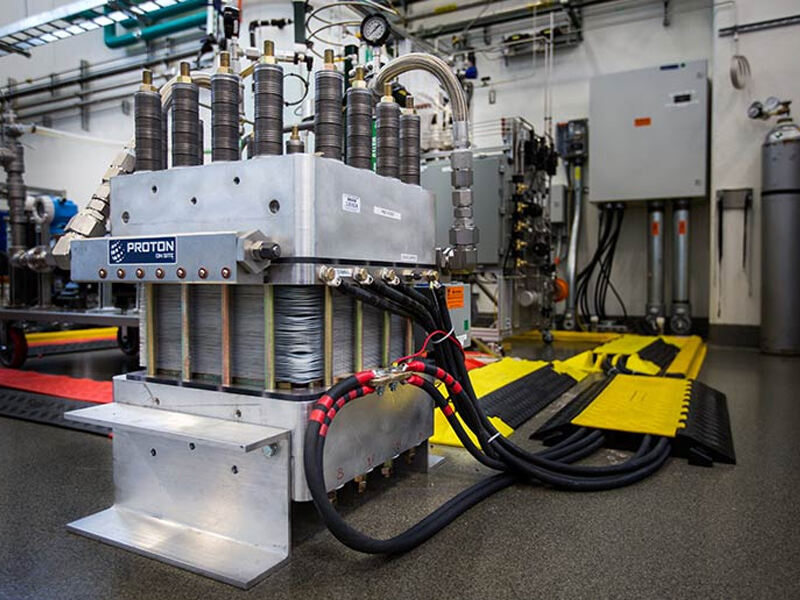

Work theory

DCOS11 series automatic switching device included 2 solo pressure reducing regulators By operating the linkage valve stem to adjust the left and right side of the outlet pressure, that is, when the left side increases, the right side decreases, and the left side supplies gas; When the right side increases, the left side decreases, and the right side supplies gas

When the gas supply side is exhausted, it automatically switches to another side Empty the depleted side of the air supply by closing the inlet diaphragm valve and opening the pressure relief diaphragm valve, then replace it with a new air supply

The priority air supply can be selected by turning the switch handle

Packing details : inner box + white box + export carton

Selling units : single unit

Sing package size : 30 x 30 x 30 cm

Sing package gross weight : 2.5 kg

Moisture Analyzer

Granularity Analyzer

O2 Analyzer

WOFLY is a leading Manufacturer, Supplier and Exporter of a wide range of gas equipments, available under the brand name AFK. Wofly's success yields from high-quality, innovative products, exceptional customer service, and unequaled technical expertise in the gas & oil industry WOFLY offers an extensive line of components including tube fittings, control valves, shut-off and solenoid valves, pressure relief and regulators. Through the years we have learned how to properly match the gas regulation equipment with the application. Using the proper equipment for the job eliminates problems such as contamination, pressure variances, safety issues, and equipment mismatch.

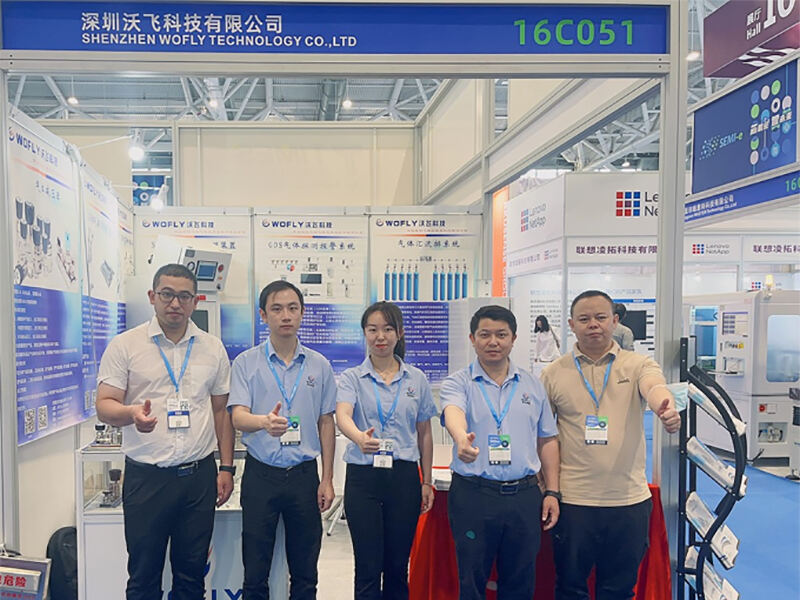

2024 APE

Wofly participated in Asia Photonics Expo(APE) 2024 to meet face-to-face with customers

2023 OCTF

Wofly participated in OCTF 2023 and widely praised by customers in Southeast Asia

Factory exhibition hall

Factory exhibition hall

More than 100 m2 Class 100 Clean Workshop

More than 1000 m2 Class 1000 Clean Workshop

CNC machine

Oil-free Helium Leak Detectors

Machining workshop

The production team is composed of a young automated production team of 30 people. With the help of customized automated tooling and test equipment, the average output of valves can reach 4000 pieces per month

Case 1 : Laboratory gas supply

Case 2 : Chemical industry gas supply

Case 3 : Industrial production gas supply

Case 4 : Fuel and lithium batteries gas supply

Wofly

The Semi-Automatic Changeover System is an device this is certainly advanced for managing the stress and flow of toxic and corrosive gases. Built with a high-temperature pressure regulator diaphragm valve meaning that the gases are controlled at optimal levels for safe and utilize this is certainly efficient

Created for use with various types of gases including toxic and gases which can be corrosive as chlorine sulfur dioxide and hydrogen chloride. The Wofly helps to monitor and regulate gas stress which is an factor that is important making certain gases are used safely and effectively in a variety of applications

The high-temperature diaphragm valve is merely an integral feature for this. Designed to withstand high quantities of heat making sure the machine can operate in environments that want a level that is a lot of control. Also fashioned with a diaphragm which helps to control pressure and movement providing a diploma this is certainly high of and consistency

Incredibly dependable and thanks which are efficient its semi-automatic procedure. Built to automatically switch between two gas sources making sure there was a supply this is certainly steady of all the time. This function is incredibly beneficial in applications that require continuous gas flow such as for instance chemical processing semiconductor and metalworking manufacturing

Simple to utilize by way of its control this is certainly intuitive panel. The system possesses interface that is user-friendly allows you for operators to create the specified force and flow levels. The system also comes with a selection of safety features pressure this is certainly including emergency shut-off valves and audible alarms making certain users in many cases are aware of any potential issues

Avail yours

Our friendly team would love to hear from you!