Centralized Gas Supply System

The centralized gas supply system for workshops represents a modernized approach to gas distribution. This system involves the design of pipelines that efficiently channel gas sources to designated points of use. This centralized supply method significantly enhances operational efficiency, reduces the consumption of human resources, ensures safety, and offers an aesthetic design. Moreover, it guarantees a more stable and smoother flow of gases.

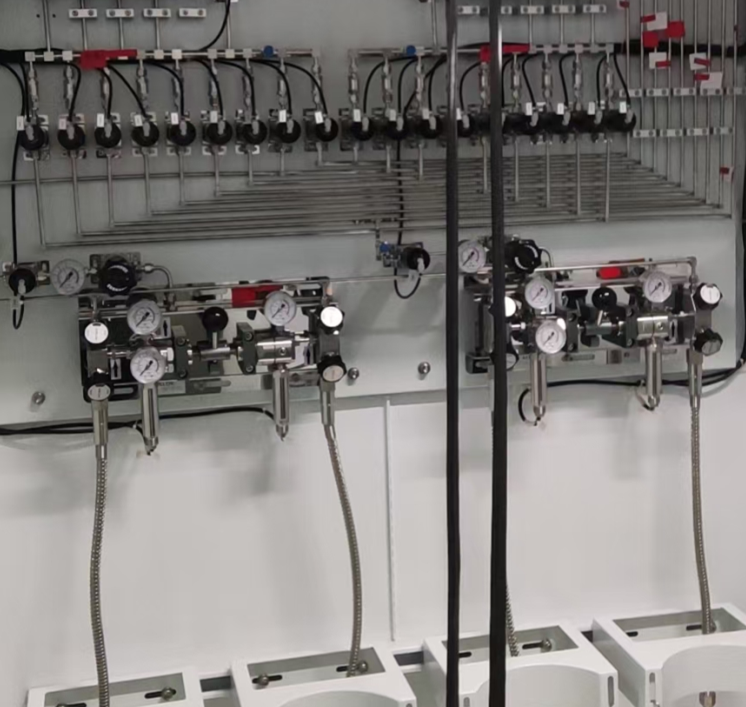

Central gas supply system, also known as centralized gas supply system, is a system that distributes gas to user terminals through a pipeline network. It mainly consists of a gas source station, switching devices, pressure regulating devices, gas transmission pipelines, a central control system, and terminal gas consumption points. This system meets the gas supply needs of users by transporting gas from a centralized gas source to the target user area.

Specifically, the centralized gas supply system works by processing gas from a central gas storage facility through switching devices and pressure regulating devices, and then delivering it to various distributed terminal gas consumption points through a pipeline system. The gas source station typically uses compressors or liquefied gas storage tanks as the source of gas supply, which is then processed, pressure-regulated, and sent into the gas transmission pipeline. The gas transmission pipeline is the core component of the centralized gas supply system, responsible for safely and stably transporting gas from the gas source station to each terminal user. The central control system monitors and controls the entire system to ensure the stability and safety of gas supply.

Compared to traditional gas supply methods, the centralized gas supply system offers numerous advantages. Firstly, it maintains the specified purity of gas and reduces the chance of impurities entering the system. Secondly, through rational pipeline design and monitoring alarm systems, it optimizes workflows and allows gas outlets to be placed directly at the point of use, improving convenience. Additionally, the centralized gas supply system helps reduce gas consumption costs, eliminate the need for cylinder management and transportation expenses, making gas supply more economical and efficient.

Currently, the centralized gas supply system is widely used in various scenarios, such as laboratories and factory workshops. With continuous technological advancements and expanding application scenarios, the centralized gas supply system is expected to become more popular and optimized in the future.

The working principle of the centralized gas supply system primarily relies on the pipeline transportation of gases. Here's a detailed explanation of how it operates:

Firstly, the gas source station serves as the starting point of the entire system. It utilizes compressors or liquefied gas storage tanks to prepare the gas for transmission through the pipeline. This preparation involves necessary processes such as treatment, purification, and pressure regulation to ensure that the gas quality and pressure meet the subsequent usage requirements.

Next, the processed gas is transported through the gas transmission pipeline to various end users. The pipeline, as the core component of the system, is made of high-strength and corrosion-resistant materials to guarantee the safe and stable transmission of gas. During transmission, the gas may pass through a series of valves, pressure reducing devices, and others to adapt to the pressure and flow requirements of different end users.

Meanwhile, the central control system plays a pivotal role in the entire process. It continuously monitors gas parameters such as pressure and flow rate through various sensors and instruments, and adjusts or controls them accordingly based on user demands or system status. For instance, when the gas consumption of a specific end user fluctuates, the central control system can automatically adjust the valve opening of the gas transmission pipeline to maintain a stable gas supply.

At the end-user side, the gas is metered through gas meters or other measuring devices before being used. These devices accurately record the user's gas consumption, providing a basis for subsequent billing.

Additionally, the centralized gas supply system is equipped with monitoring and alarm devices. In case of any abnormalities in the system, such as gas leaks or pressure irregularities, these devices immediately trigger alarms and, in emergency situations, can remotely shut off the gas supply through a safety shutdown system, thus ensuring the safety of personnel and equipment.

In summary, the centralized gas supply system achieves centralized gas supply, management, and safe usage through rational pipeline design, precise control systems, and reliable monitoring and alarm devices. This method of gas supply not only enhances efficiency, reduces human resource consumption, but also ensures more stable and smooth gas output, meeting the high demands of modern industrial production for gas supply.

EN

EN

AR

AR

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ