Wofly is a leading manufacturer and exporter of EP/BA diaphragm valves, pressure regulator, instrument valves, needle valves, hydrogen energy valves, check valves, filters, measuring devices, VCR micro-welded pipe fittings, ultra-high purity fittings, as well as special gas equipment (GC/GR/MB/MP/VDB/VDP), automatic switching systems, and gas manifolds, renowned for its commitment to excellence in product design and quality. Wofly, backed by a team with over 13 years of expertise, is an ISO 9001-certified organization committed to delivering world-class products while maintaining strict adherence to international quality standards.

Wofly's fully integrated manufacturing facility is equipped with state-of-the-art infrastructure and precision CNC machines. Operating in a clean Class 100 environment, our products undergo rigorous quality control at every step, from raw material selection to modern CNC machining and precise assembly. WOFLY's products are manufactured to the highest standards of performance and reliability. They are CE certified and conform to European EN 3.1, Rohs, and ATEX international standards.

At Wofly, we engineer products that meet the stringent norms of over 100 countries, ensuring global compatibility and reliability. Each product undergoes meticulous testing, including pneumatic proof tests, hydrostatic proof tests, hydrostatic burst tests, impulse tests, vibration tests, and tensile tests, to guarantee its durability and performance.

Our products cater to a wide range of industries, including oil and gas exploration, oil refineries and petrochemicals, process instrumentation, power generation, CNG/PNG and natural gas distribution, marine and shipbuilding, and the defense industry.

Industry Experience

Happy Customer

Export to Country

Cleaning Room

Company Staff

CNC Machine

We hold important position in our key markets: semiconductor, integrated circuit, optoelectronics, new energy, microelectronics, biopharmaceuticals, research institute, standard testing and anode material.

The electronic special gas pipeline system specifically refers to the management and transportation of highly hazardous specialty gases such as SiH4, NF3, and Cl2, where safety is paramount.

The centralized gas supply system for workshops represents a modernized approach to gas distribution. This system involves the design of pipelines that efficiently channel gas sources to designated points of use. This centralized supply method sig...

The bulk gas delivery system is a specialized system designed for storing, transporting, and utilizing large quantities of gases. It primarily consists of a gas supply system and a pipeline system.

The Encapsulation is necessary for the semiconductor electronic chip manufacturing process.

Here you can view the latest exhibition news of the company and the latest information of the company

07

Industry: global industrial gases market size of 175.5 billion U.S. dollars in 2025, 2020-2025 CAGR5.4%, track both stability and growth

Discover More14

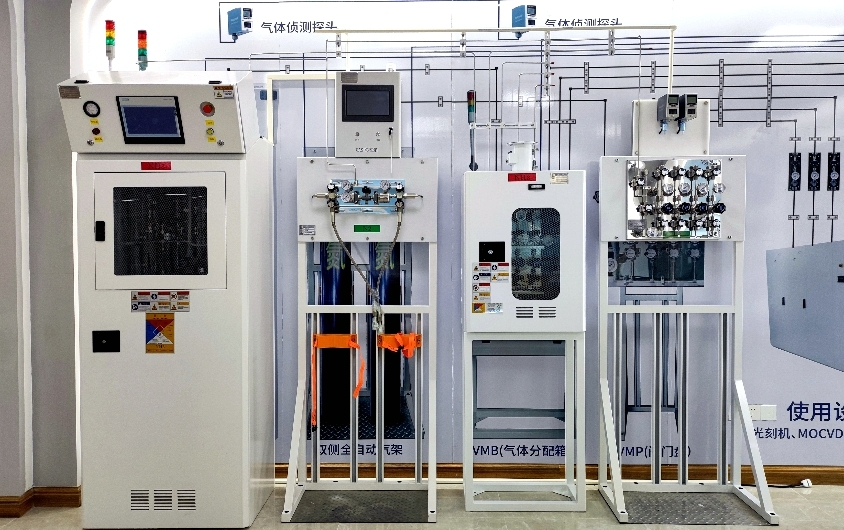

Semi-automatic switching device is applied to decompression gas supply of double-sided high-pressure gas cylinders to realize continuous gas supply with blowing function by automatic switching, which is widely used in the fields of semiconductors and electronics, medical treatment, gene technology, biopharmaceuticals, scientific research and so on.

Discover More

Industrial gases refer to products that are gaseous at room temperature and pressure, and are the basic raw materials of modern industry, widely used in traditional and emerging industries.